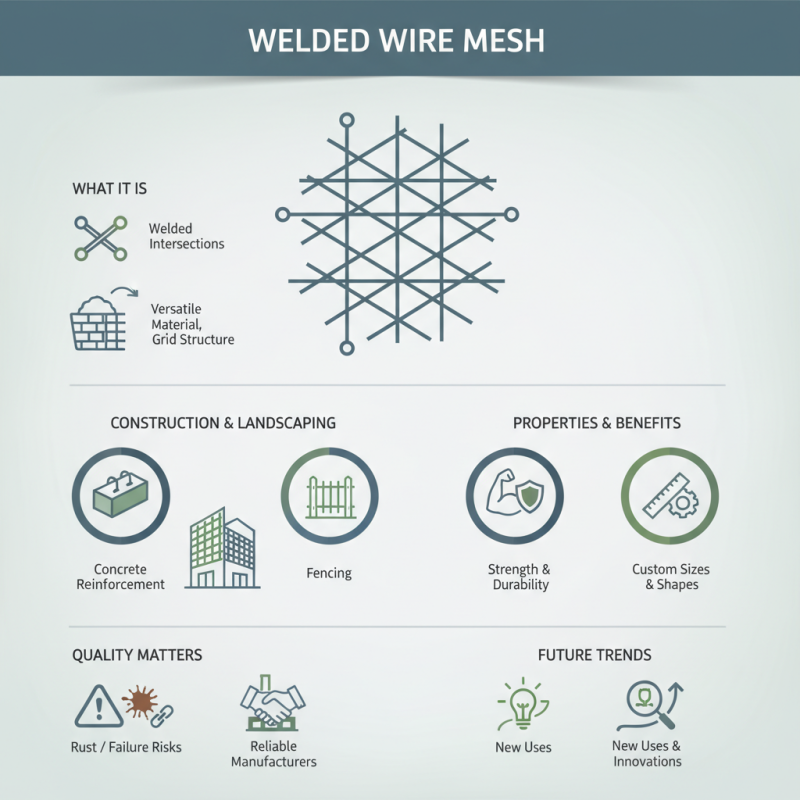

welded wire mesh is a versatile material widely used in various industries. It consists of wires that are welded together at intersections, creating a grid structure. According to industry expert John Smith, "Welded wire mesh is essential for construction and landscaping applications." Its unique properties make it a favorite among builders.

This mesh provides strength and durability, essential for structural support. It is used in concrete reinforcement, fencing, and even architectural designs. The precision in its manufacturing allows for custom sizes and shapes, catering to specific project needs. However, not all applications suit this material perfectly.

Some users may overlook the importance of quality in welded wire mesh. Inferior products can lead to issues like rust or structural failure. It's crucial to source from reliable manufacturers. The industry continues to evolve, introducing new uses and innovations. Reflecting on these developments can help maximize the benefits of welded wire mesh.

Welded wire mesh consists of intersecting wires that are welded together at their junctions. It typically features a grid pattern, with precise spacing between the wires. Common materials used in its production include stainless steel and galvanized steel. The choice of material affects durability and rust resistance.

The mesh can vary in thickness, which contributes to its overall strength and versatility. It is often used in construction, agriculture, and even in crafting. For example, people utilize it for reinforcing concrete structures and creating fences. Each application calls for specific dimensions and wire gauges to meet the needs of the project.

However, not all mesh is created equal. Some may lack sufficient strength for heavy-duty applications. Users should consider their specific requirements carefully. Testing different options before making a decision is often necessary. Understanding the composition and limitations of welded wire mesh can lead to more effective and lasting results.

Welded wire mesh is a robust material often used in construction and agriculture. The manufacturing process of welded wire mesh begins with the selection of high-quality steel wire. This wire is drawn to specific diameters, usually ranging from 1.5mm to 5mm, depending on the intended use.

Next, the wires are arranged into a grid layout, with precise spacing typically between 50mm to 200mm. High-frequency welding is then employed to join the intersecting wires. This process ensures a strong bond. According to recent industry reports, welded wire mesh has a tensile strength of up to 500 MPa, making it ideal for various structural applications.

After welding, the mesh undergoes surface treatment, often including galvanization. This step is crucial for enhancing corrosion resistance. In fact, industry studies show that galvanized wire mesh can increase lifespan by up to 30%. However, challenges remain. Not all manufacturers adhere to the same quality standards, leading to variability in product performance. The sustainability of steel sources is also a growing concern as demand increases.

Welded wire mesh is a versatile material used in various construction applications. Its structure consists of steel wires arranged in a grid and welded at their intersections. This makes it strong and durable, ideal for different settings. In construction, it’s often used for reinforcing concrete. The mesh provides stability and prevents cracks, increasing the lifespan of structures.

One common application is in concrete slabs. Welded wire mesh helps distribute weight evenly. This is critical in heavy-load areas, like parking garages. It can also be found in walls, providing extra support. Builders often use it for fences as well. They provide security while allowing visibility. However, improper installation can lead to ineffective reinforcement.

Tips: Always verify the gauge of the wire. A thicker gauge may be necessary for larger projects. Consider the spacing of the mesh as well. Closer spacing can improve strength but may increase costs. Regular inspection is key to ensuring longevity. A few missed welds could compromise the entire structure. Always consult with professionals when in doubt.

Welded wire mesh plays a significant role in the industrial sector, especially in security and fencing applications. This durable product, composed of longitudinal and transverse wires welded at each intersection, offers structural integrity. According to recent industry reports, the global market for welded wire mesh is expected to grow at a pace of 6% annually. This rise reflects a greater reliance on strengthened security systems in various facilities.

In industrial settings, welded wire mesh is commonly used for fencing. It provides an effective barrier for different environments, from warehouses to manufacturing plants. The mesh can deter unauthorized access, reducing theft and vandalism. Reports indicate that facilities employing welded wire mesh fencing have seen a 30% decrease in security breaches. However, there are challenges. Some environments may require additional reinforcement to withstand extreme weather or physical impacts.

Additionally, welded wire mesh is favored for storage cages and enclosures. These structures allow visibility while securing valuable assets. However, improper installation can lead to vulnerabilities. Observing proper practices is essential. Overall, welded wire mesh's adaptability and strength make it a preferred choice, but some aspects warrant careful consideration to optimize its effectiveness.

Welded wire mesh is known for its strength and versatility. It is crafted from thin wire strands that are welded together at intersections. This structure provides significant durability, making it suitable for various applications. However, its longevity greatly depends on maintenance practices.

Regular inspections help identify any signs of wear and tear. Rust can become an issue if the mesh is not properly coated or if it's exposed to moisture. Keeping the mesh clean is essential. Accumulated dirt can hide underlying problems. It's advisable to wash it periodically, focusing on areas prone to corrosion.

In harsh environments, using protective coatings enhances durability. Still, nothing lasts forever. Over time, welded wire mesh will show signs of aging. It's crucial to replace sections if corrosion becomes extensive. This simple action can prevent larger structural failures. Reflecting on these maintenance tips can lead to better use of welded wire mesh products.